We, being an ISO 9001:2015 Certified organization, are discrete and conscious of our responsibility to abide by and adherence to observance of normative requisites in maintaining of Quality Measures through stringent quality regulation surveillance and controls at our organization.

With process supported by all requisites at our well-developed Quality Testing Unit, we assure of Quality Attributes of the Range of our Baby Care Products in accordance with FDA, ISO and BIS standards.

We pursue Quality Management through effective handling of production cycle and the same is also duly tuned and honed so as to remain effective in achieving high quality standards.

Our team of Quality Operatives also ensure use of Quality Inputs to manufacture the Product. They also exercise strict controls at the following stages:

- Inspection of raw material at the time of procurement

- Supervision while processing

- Assurance of quality packaging

- Random checking at the time of dispatch

- Ascertaining a close supervision of the delivery procedure

Under this quality control process, in particular the "Printing Inks" used for print designing of plastic feeding bottles, undergo coherent Testing and Checks to determine the ink's conformity to following:

Quality is an integral part of our corporate culture & heritage. Total Quality Management has been in practice with us from the very beginning and is further validated from the fact that ours is a ISO 9001:2015 Certified company and our products are FDA Approved. Moreover, all our products confirm to BIS Standards. Quality is monitored at all stages of production viz procurement of raw materials, processing, packaging, dispatch, and delivery process of the finished goods to the clients.

The use of well selected raw material, advanced production technology, skilled workforce and demanding quality control processes are also well directed by an efficient management system to ensure world-class products at competitive prices. Strict quality control procedures are followed to ensure that the products meet international standards in quality.

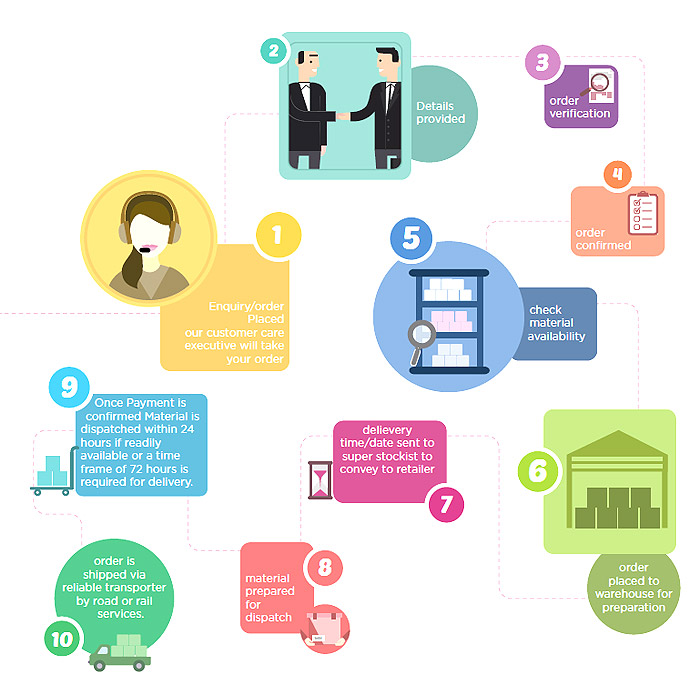

Our Quality Assurance also ensure that entire process, from initial customer order through to final delivery, is carried out in the most efficient and cost-effective manner. Regular internal procedure audits are also conducted to make sure that all the systems are perfectly coordinated and that any necessary improvements or changes are brought into action immediately.

![]() Quality

Quality